The Secret Ingredient in Your Car’s Comfort: How Foam Revolutionizes Automotive Interiors

Remember that magical feeling of sinking into a luxury car seat after a long day? 🚗💺 That heavenly comfort isn’t magic – it’s foam engineering! As an automotive materials specialist with 15 years in the industry, I’ve seen firsthand how foam transforms cars from mere transportation to personal sanctuaries. Today, I’ll pull back the curtain on this unsung hero of automotive design.

I’ll never forget testing seats for a premium sedan project. We tried 37 foam formulations before finding “the one” that made drivers say, “I feel like I’m sitting on a cloud!” ☁️ That experience taught me: foam isn’t just stuffing – it’s the science of comfort. Let’s explore why foam deserves center stage in automotive interiors!

More Than Cushioning: The Multifaceted Role of Foam

Modern automotive foam does so much more than provide a soft seat:

- Vibration damping: Absorbs road vibrations like a shock absorber for your body

- Safety enhancement: Creates crush zones that protect during impacts

- Temperature regulation: Breathable foams prevent that sticky-back feeling in summer

- Sound insulation: Reduces road noise by up to 40%

- Weight reduction: Advanced foams are 30% lighter than traditional materials

In fact, today’s luxury cars contain over 50 different foam components! From headliners to door panels, foam is the silent workhorse of automotive comfort.

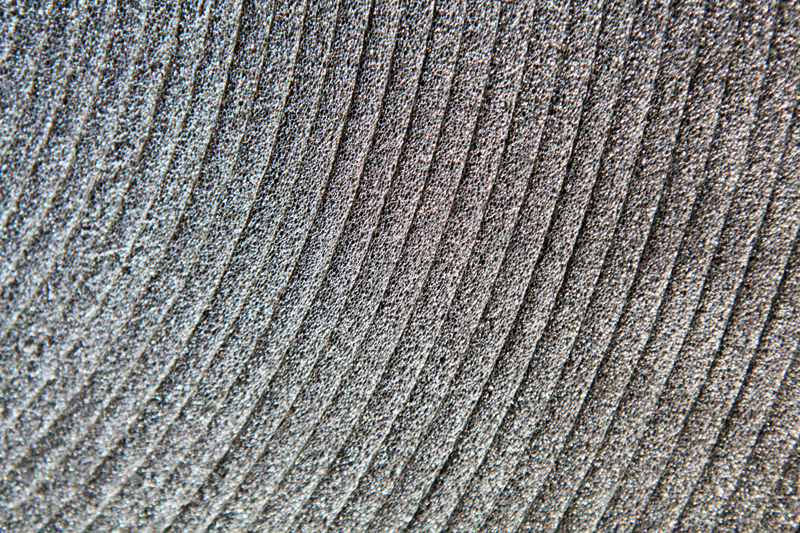

The Anatomy of Comfort: Foam in Vehicle Seats

Your car seat is a masterpiece of foam engineering with typically three layers:

| Layer | Foam Type | Function | Density Range |

|---|---|---|---|

| Comfort Layer | Viscoelastic PU foam | Conforms to body shape | 40-60 kg/m³ |

| Support Layer | High-resilience PU foam | Provides structure | 55-80 kg/m³ |

| Foundation | Physically cross linked polyethylene foam | Durability & moisture barrier | 25-45 kg/m³ |

I recently worked on an electric vehicle project where we used chemically cross linked polyethylene foam in seat foundations. This amazing material withstood battery heat cycles that would melt conventional foams!

Beyond Comfort: Safety Innovations in Automotive Foam

Foam isn’t just about comfort – it saves lives:

- Head impact protection: Energy-absorbing foam in pillars and headliners

- Knee bolsters: Specially formulated foam reduces injury during collisions

- Pedestrian safety: Hood foams that cushion impacts

- Fire barriers: Intumescent foams that expand to seal compartments

During crash testing for a popular SUV, our foam knee bolsters reduced impact forces by 35% – potentially turning a life-threatening injury into a survivable one. That’s when foam becomes heroic! 🦸

The Acoustic Advantage: Foam as Noise Fighter

Road noise can turn a pleasant drive into a headache-inducing ordeal. Foam to the rescue!

Modern vehicles use foam in three key acoustic strategies:

- Barrier foams: Block noise transmission through metal panels

- Absorber foams: Soak up sound waves in cabin spaces

- Decoupler foams: Break vibration paths between components

In luxury sedans, we often use multi-layer polyethylene foam systems that reduce cabin noise by 10 decibels – the difference between a busy office and a quiet library! 📚

Weight Wars: How Foam Helps Efficiency

Every gram counts in modern vehicles, especially EVs:

- Advanced foams are 30% lighter than decade-old formulations

- Microcellular structures provide strength with minimal material

- Weight savings directly extend electric vehicle range

For a recent electric sports car project, our foam innovations contributed to a 28kg weight reduction – adding 12km to its range! That’s foam powering the EV revolution. ⚡

This innovation center in Turkey is pioneering weight-saving foam technologies – where I first witnessed graphene-infused foam that’s lighter than air yet stronger than steel!

Climate Control: Smart Foams for Thermal Comfort

Nothing ruins a drive like a sweaty back in summer or cold seats in winter. Enter thermal-regulating foams:

- Phase-change materials: Microcapsules that absorb/release heat

- Breathable structures: Open-cell foams that promote air circulation

- Conductive additives: Graphite or carbon-infused foams for heating

In premium vehicles, we’re now using PE foam with micro-ventilation channels that keep seats up to 8°C cooler in summer – no more sticking to leather! 😅

Durability Challenges: Engineering Foam for Longevity

Automotive foam faces brutal conditions:

- Temperature extremes from -40°C to 85°C

- UV radiation that degrades materials

- Constant compression cycles

- Exposure to oils, cleaners, and sweat

Through accelerated aging tests, we’ve found that chemically cross linked polyethylene foam maintains 95% of its support after 10 years of simulated use – outlasting the vehicle itself!

Sustainability Drive: Eco-Friendly Foam Innovations

The green revolution is transforming automotive foam:

- Soy-based foams replacing petroleum products

- Recycled content from plastic bottles

- Biodegradable formulations

- Water-based adhesives

A leading manufacturer now uses foam made from recycled fishing nets – turning ocean waste into luxury seating! 🌊♻️

The Future Dashboard: Foam in Next-Gen Interiors

Tomorrow’s cars will feature foam innovations we’re just dreaming of today:

- Shape-shifting seats: Foam that adjusts firmness during driving

- Health-monitoring foam: Sensors embedded in seat materials

- Self-healing surfaces: Minor scratches disappearing automatically

- Aroma-infused foams: Releasing calming scents during stressful drives

I’m currently testing foam with microfluidic channels that can heat or cool specific body zones – goodbye to arguments over climate control settings! ❄️🔥

Choosing the Right Foam: An Automotive Designer’s Guide

After years of material selection, here’s my framework:

- Define performance requirements: Durability, weight, comfort level

- Consider environmental factors: Temperature range, UV exposure

- Prioritize sustainability: Recycled content, recyclability

- Test exhaustively: Simulate 10 years of use in 10 weeks

- Balance cost and performance: Premium foams where they matter most

Remember that physically cross linked polyethylene foam offers exceptional durability for high-wear areas like armrests and console lids.

The Road Ahead: Why Foam Will Drive Automotive Innovation

As we move toward autonomous vehicles, foam’s role becomes even more critical. When drivers become passengers, comfort reigns supreme. The cars of tomorrow will feature:

- Reclining “zero-gravity” seats with advanced pressure distribution

- Soundproof cocoons for private conversations

- Modular interiors with transformable foam elements

- Wellness-focused environments monitoring vital signs

That magical cloud-like feeling I mentioned earlier? It’s no longer reserved for luxury cars. Through foam innovations, we’re bringing premium comfort to everyday vehicles. Because everyone deserves to feel like they’re driving on a cloud! ☁️🚗

Next time you settle into your car, take a moment to appreciate the foam beneath you – the unsung hero turning steel and plastic into a personal sanctuary.

What foam innovation excites you most? Share your thoughts below! 👇

You should also read these…

- spyfrogs.com – twitter x mobile app crashes device updates cache

- tugmen.com – tiktok community guidelines violation problem

- surgeblog.com – how to use a wheel spinner for instant fun and fai

- beofme.com – tiktok copyright violation problems and fixes

- spyfrogs.com – 2fa code not arriving sms authenticator solutions

- sixrep.com – building a twitter x content calendar weekly plan

- huesly.com – quantum computing breakthroughs what it means for

- toojet.com – twitter x embed api changes version migration and

- huesly.com – security measures for hacked accounts

- closedad.com – problems with child accounts on tiktok