Hey there! 👋

As someone who’s spent over a decade helping clients choose the perfect foam materials, I’ve seen firsthand how density and compression can make or break a product. Remember that time I convinced a furniture manufacturer to switch from low-density to medium-density foam? Their customer complaints dropped by 70% in six months! 🛋️✨

Why Foam Properties Matter More Than You Think

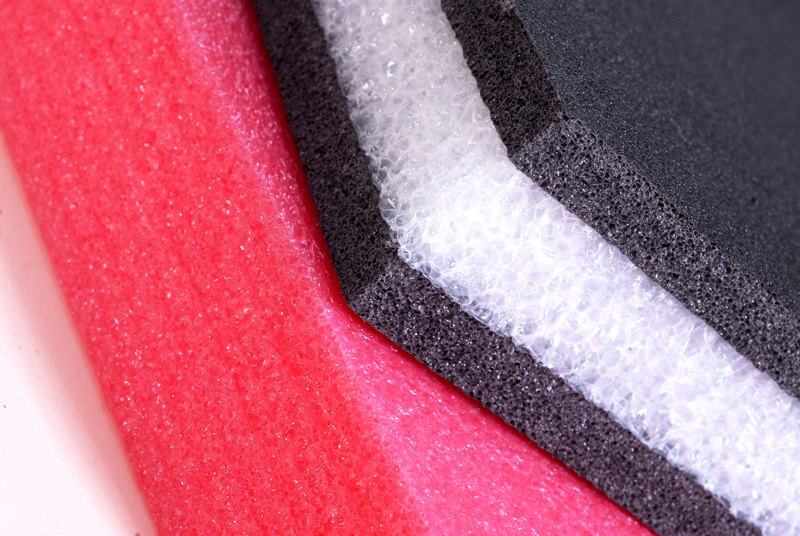

Foam isn’t just “squishy stuff” – it’s precision engineering at its finest! Density (measured in kg/m³) tells us about the material’s weight and cell structure, while compression strength (measured in kPa) reveals how it performs under pressure. Think of density as the foam’s DNA 🧬 and compression as its fitness level 💪.

During my early days in the industry, I learned this lesson the hard way when we used low-density polyethylene foam for bicycle seat packaging. The result? A warehouse full of damaged goods. 😫 That’s when I became obsessed with material science!

The Density-Compression Tango: How They Interact

Higher density usually means better durability, but it’s not always that simple. I like to explain it using a cake analogy: A dense pound cake holds its shape (high compression), while angel food cake collapses easily (low compression). 🎂

| Foam Type | Density Range (kg/m³) | Compression Strength | Best Applications |

|---|---|---|---|

| Low-Density PE | 20-30 | Light cushioning | Packaging fillers |

| Medium-Density PE | 30-60 | Moderate support | Mattress toppers |

| High-Density physically cross linked polyethylene foam | 60-200 | Structural support | Industrial padding |

Just last month, an athletic gear client asked why their pe foam knee pads were failing. Turns out they prioritized ultra-light density without considering compression resistance during impact. We fixed it with a layered approach!

Real-World Selection Strategies

Here’s my golden rule: “Density determines lifespan, compression defines performance.” For medical device packaging, I always recommend chemically cross linked polyethylene foam because it offers that perfect balance of sterilization resistance and cushioning.

Consider automotive seating: Luxury cars use multi-density zones (soft for comfort, firm for support) while maintaining consistent compression recovery. It’s like creating a foam symphony! 🚗🎶

The Cost-Performance Balancing Act

Many clients initially balk at high-density foam prices. But let me share a game-changing case study: A shipping company switched to high-compression polyethylene foam and reduced product damage by 45%, saving $220K annually in returns. 💰 The ROI spoke louder than any sales pitch!

My Top 3 Density Mistakes to Avoid:

- The “Firmness Fallacy” 😓: Assuming high density = extra firm (compression determines feel!)

- One-Size-Fits-All Approach 📦: Using identical foam for electronics and furniture

- Ignoring Environmental Factors 🌡️: Temperature changes affect compression resistance

Future-Proofing Your Foam Choices

With sustainability becoming crucial, I’m loving the new generation of recycled high-density foams that maintain compression integrity through 10,000+ cycles. ♻️ One client even achieved LEED certification by switching to these!

Remember my friend who started that yoga mat company? By selecting foam with 45kg/m³ density and 25kPa compression strength, she created mats that cushion joints without losing stability. Now she’s shipping worldwide! 🧘♀️🌎

The Final Squeeze: Key Takeaways

After helping hundreds of clients, here’s my compressed wisdom (pun intended!):

- 📏 Test density AND compression together – they’re dance partners, not solo performers

- ⏳ Prioritize long-term performance over short-term cost savings

- 🔬 Demand material certifications from suppliers

Choosing foam without understanding density and compression is like baking without measuring ingredients. 🎂⚖️ When you get this duo right, you create products that feel magical to customers.

So go forth and select wisely – your perfect foam match is out there! ✨

You should also read these…

- hogwar.com – directx errors common graphics problems in games

- beofme.com – creative ways to use spin the wheel for fun conten

- olddry.com – how to create your own custom wheel for any occasi

- olddry.com – the dark side of social media algorithms

- beofme.com – border clashes in southeast asia a framework for c

- sixrep.com – tiktok action could not be completed warning

- olddry.com – can ai actually be creative

- axtly.com – cant add product links on tiktok

- tugmen.com – beginner plyometric moves to boost cardio

- noepic.com – local live music events you can attend on a tight