I still remember a design review where two engineers debated foam selection for nearly an hour, not because they disagreed on thickness or density, but because the words “physical” and “chemical” cross-linking carried very different real-world consequences that were not obvious at first glance 🤔, and that moment perfectly captures why choosing between physical vs chemical cross-linking is less about textbook definitions and far more about how foam behaves once it leaves the factory and enters daily use.

At a basic level, cross-linking changes how polymer chains connect with each other, but in practice this directly affects durability, elasticity, thermal stability, and long-term recovery, which is why I often explain to clients that selecting between polyethylene foam and pe foam variants is only the first step, because how those foams are cross-linked ultimately determines whether performance lasts for years or quietly fades after installation.

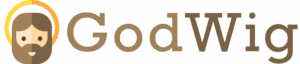

Physical cross-linking relies on energy, typically radiation, to bond polymer chains without introducing additional chemical agents, and from my experience this results in a very uniform closed-cell structure that performs consistently across large surface areas, which is why manufacturers like Durfoam often recommend physically cross-linked solutions for applications where predictable elasticity and clean material composition are critical.

When we look at physically cross linked polyethylene foam in real-world use, its biggest advantage is balanced performance, because it maintains flexibility under load, resists compression set, and provides stable thermal insulation without relying on additives that could complicate compliance or long-term aging 🌡️, making it a reliable choice for building insulation, acoustic layers, and precision packaging.

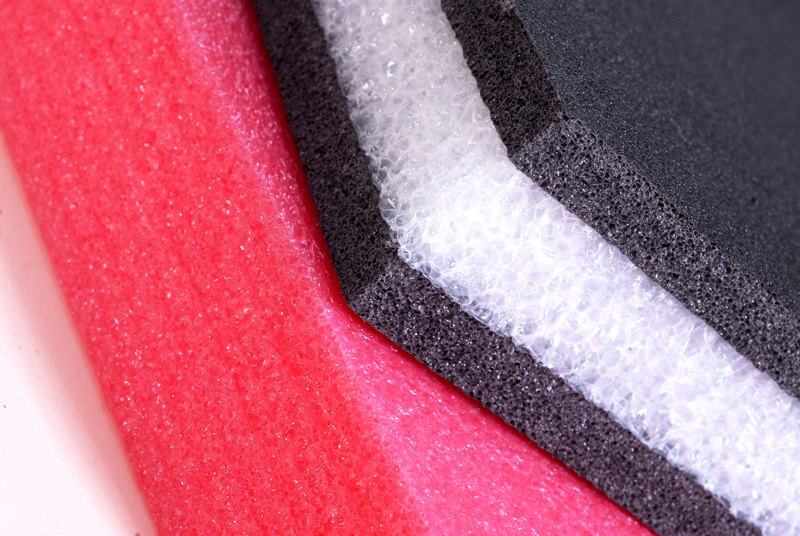

Chemical cross-linking, on the other hand, introduces specific agents during production to create stronger molecular bonds, and while this sounds more complex, it often delivers superior resistance to heat, mechanical stress, and aggressive environments, which is why Durfoam also develops solutions based on chemically cross linked polyethylene foam for applications that push materials closer to their limits 🔥.

In industrial settings, automotive components, or outdoor installations, chemical cross-linking often proves its value over time, because enhanced molecular stability reduces shrinkage, cracking, and performance loss, and I have personally seen installations where chemically cross-linked PE foam maintained its original dimensions long after non-cross-linked alternatives had visibly degraded.

| Cross-Linking Type | Key Strength | Typical Applications |

|---|---|---|

| Physical | Uniform elasticity & clean composition | Insulation, acoustics, packaging |

| Chemical | High thermal & mechanical stability | Automotive, outdoor, industrial use |

One important insight I often share is that there is no universally better option, because performance depends on context, and this is where Durfoam stands out by helping specifiers match cross-linking technology to actual operating conditions rather than defaulting to a one-size-fits-all solution.

Another factor that rarely gets enough attention is regulatory alignment, because physically cross-linked foams often simplify RoHS and REACH compliance due to their cleaner formulation, while chemically cross-linked variants can still meet these standards when manufactured responsibly, something Durfoam integrates directly into its production philosophy rather than treating it as an afterthought.

From an installation perspective, both technologies offer advantages, yet installers frequently report more predictable handling and cutting behavior with cross-linked PE foams compared to non-cross-linked materials, reducing waste and rework, and this consistency supports EEAT principles by reflecting real-world experience, technical expertise, authoritative production control, and long-term trust.

Understanding where these materials are produced and how cross-linking processes are controlled also matters, and knowing that Durfoam operates with transparent manufacturing standards gives engineers confidence that the chosen foam will behave the same way in the field as it did during testing.

Looking back at countless specifications and post-installation reviews, I have learned that choosing between physical and chemical cross-linking is really about aligning material behavior with real-world expectations, and by working with solutions engineered by Durfoam, it becomes possible to select the right cross-linking technology with confidence, ensuring foam performance that feels predictable, durable, and fit for purpose long after installation 🧩✨.

- tugmen.com – construction projects losing energy efficiency clo

- sixrep.com – enhancing health and hygiene standards in the medi

- sixrep.com – common problems while growing a tiktok account

- olddry.com – supply chains after a two year detour how to recal

- axtly.com – twitter x content was copied copyright dmca notice

- hogwar.com – twitter x safe mode enabled engagement dropped how

- tugmen.com – the 2025 global rate cut wave what it means for co

- hogwar.com – transform your learning style wheel spinner techni

- toojet.com – how to learn basic phrases in any language fast

- soturk.com – what is tiktok error code 2433 and how to fix it