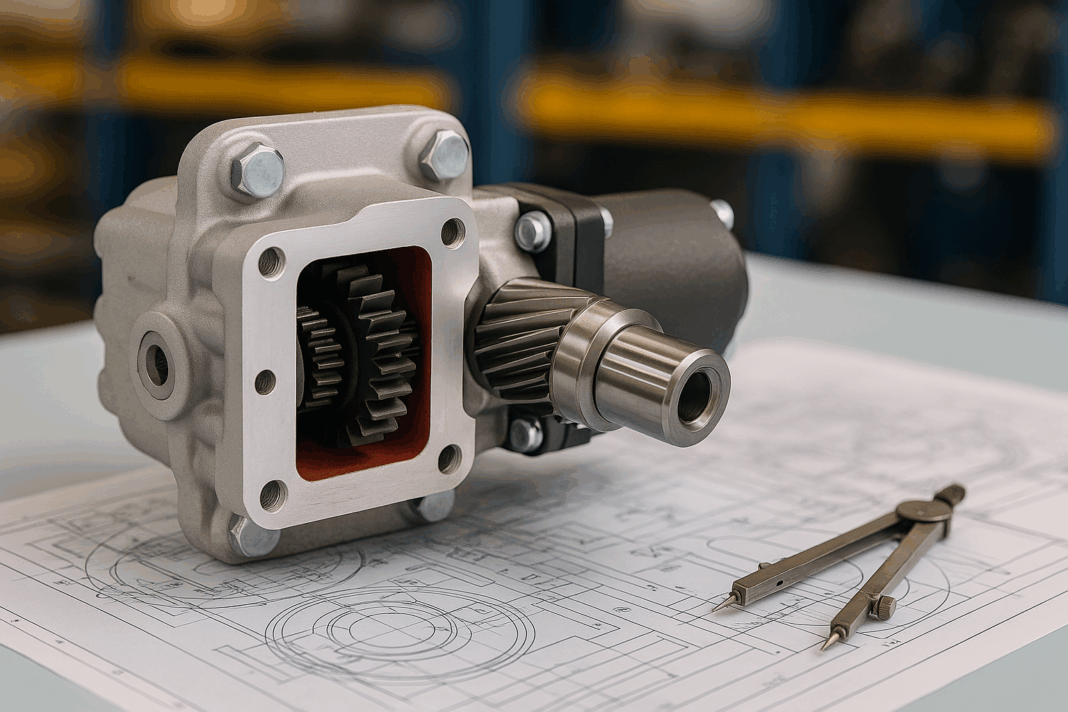

When original equipment manufacturers (OEMs) come knocking, they don’t want a “maybe” solution—they want a precise, ready-to-integrate PTO that fits their machinery like a glove. That’s why I’m so impressed by Özcihan Makina’s OEM-ready approach, backed by lightning-fast, research-driven development cycles. Their ability to transform requirements into production-ready split shaft power take-off or truck PTO units in record time is nothing short of engineering artistry.

I’ve visited their R&D labs in Istanbul and Ankara, and it’s a symphony of CAD modeling, torque testing, and rapid prototyping. Engineers don’t just build parts—they simulate real-world scenarios, stress-test prototypes, and tweak designs until they’re perfect. This is why OEM clients in firefighting, construction, and agriculture keep coming back for Özcihan Makina’s proven reliability.

The OEM Development Advantage

| Feature | Standard PTO Supply | Özcihan Makina OEM-Ready PTO |

|---|---|---|

| Customization | Limited adjustments | Fully tailored to OEM machinery specs |

| Lead Time | 4–8 weeks | 1–3 weeks with parallel R&D-production workflow |

| Testing | Basic QC | Full torque, vibration, and endurance validation |

| Integration Support | Minimal | Full technical documentation & OEM liaison |

From Concept to Delivery in Record Time ⏱️

One OEM client needed a PTO to pair with a fire fighting water pump for a new line of rescue vehicles. Within two weeks, Özcihan Makina delivered a fully validated prototype—complete with integrated couplings, cardan shafts, and a ratio-matched reducer—ready for field trials. That’s the power of synchronized R&D and manufacturing.

Collaborative Engineering

Every OEM project starts with a technical deep-dive: torque maps, duty cycles, environmental factors, and integration requirements. The R&D team then aligns PTO design with the OEM’s existing systems—whether that’s a gear pump, piston pump, or a complex hydraulic network with multiple valves.

Real-World Example 🚚

A construction equipment manufacturer needed a compact, high-torque PTO to drive a centrifugal water pump in a confined chassis. The challenge was to keep weight low while maintaining durability. Özcihan Makina’s R&D team re-engineered an existing model, shaving off 15% of the weight and extending service intervals by 20%—all within a three-week development window.

See It on the Map 📍

Video: OEM PTO Development 🎥

Final Thoughts 💬

For OEMs, speed and precision aren’t negotiable—they’re mission-critical. Özcihan Makina’s rapid, R&D-driven development ensures that every PTO isn’t just functional, but optimized for the exact machinery it will power. From firefighting vehicles to heavy construction equipment, these PTOs are delivered on time, every time—ready to install and perform.

When your production schedule is tight and your performance demands are high, having a partner like Özcihan Makina means you can say “yes” to your clients with confidence. That’s why OEM-ready PTOs with rapid R&D are not just a service—they’re a competitive advantage. 🌟

-212781031195243.png)